Smart DC-DC Converters with MPPT + AI: Unlocking Peak Efficiency in Green Hydrogen Electrolysers

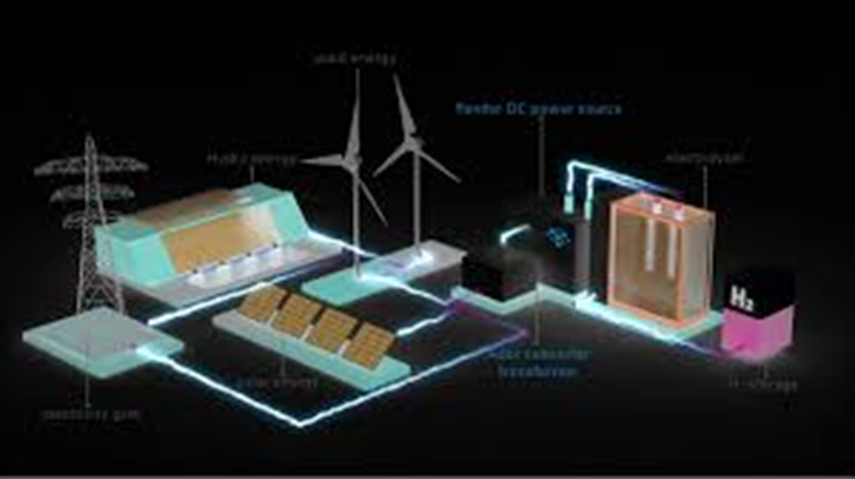

According to the IEA, the global hydrogen demand is projected to hit 180 million tonnes by 2030. However, the challenge is to produce hydrogen efficiently, as it remains expensive, and even a small loss directly impacts the levelized cost of hydrogen (LCOH). This is where the DC-DC Converter comes in. The advanced converters are equipped with maximum power point tracking (MPPT), and even AI-driven controls are unlocking unprecedented efficiencies in green hydrogen production. For engineers and investors, building scalable, reliable, and cost-effective electrolyser plants is crucial for competing in the future energy market.

In this article, we will explore how DC-DC converters are reshaping hydrogen production.

Let’s start!

1. Modular DC-DC Converter Design

The modular design of the modern DC-DC converters is one of the most powerful features. Instead of multiple electroyser stacks from a single massive converter, each stack is paired with its own unit.

This design has several benefits:

- Redundancy: keeps hydrogen production uninterrupted. If one converter goes offline, the others continue running.

- Scalability: Adding more stacks is as simple as plugging in additional DC-DC converters.

- Maintainability: Fault isolation is easier, minimizing system-wide disruptions.

2. Efficiency Gains with MPPT: Extracting Every Watt from Renewables

Renewable power sources fluctuate based on sunlight, wind speed, and other factors, and therefore do not deliver constant outputs. That causes inefficiency if not managed properly.

That’s where MPPT enters. By continuously adjusting operating parameters, it ensures that the DC-DC converter draws maximum power from the renewable sources at any moment.

3. Avoiding Conversion Losses: Direct DC-to-DC Power Delivery

A key pain point in many hydrogen plants is conversion waste. Traditional systems often convert DC power from renewables into AC, and then back to DC for electrolysis. Each conversion step eats into efficiency, generating heat instead of useful hydrogen.

For operators, this means:

- Lower energy bills (less wasted electricity).

- Smaller cooling systems (less heat generated).

- Higher hydrogen yield with the same renewable capacity.

It’s a classic case of doing more with less.

4. AI-Powered MPPT: Smarter, Faster, and Adaptive

The next frontier for DC-DC converter technology is artificial intelligence. While traditional MPPT algorithms adjust for maximum power under changing conditions, AI-enhanced MPPT takes it further with predictive capabilities and ultra-fast response times.

Why does this matter for hydrogen? Renewable inputs are unpredictable. Fast, intelligent control ensures electrolysers always operate in their optimal window, improving not just energy efficiency but also stack durability.

AI also enables predictive maintenance—spotting anomalies in converter performance before they lead to downtime, which is a big win for reliability.

5. Choosing Between Isolated and Non-Isolated Converters

Not all hydrogen plants have the same design needs. Here’s where choosing the right type of

DC-DC converter makes a difference:

- Non-isolated converters:

- Compact, lightweight, and simpler.

- Higher efficiency due to fewer components.

- Ideal when galvanic isolation isn’t mandatory, such as local renewable-to-stack connections.

- Isolated converters:

- Provide galvanic isolation, which enhances safety and security.

- Help in balancing systems with different grounding schemes.

- Useful in large, distributed electrolyser plants with long transmission paths.

According to Springer, non-isolated converters are increasingly popular in hydrogen projects due to their efficiency and cost benefits. Still, safety and grid integration requirements may make isolated topologies the better choice in some projects.

The right pick often comes down to balancing efficiency, cost, and safety.

6. Engineering Flexibility for Real-World Conditions

Beyond efficiency, smart DC-DC converters are engineered for the messy reality of hydrogen projects:

- Voltage mismatches between renewable generation and electrolyser stacks.

- A long cable runs across large hydrogen plants.

- Sudden start-ups or shutdowns due to renewable variability.

Modern converters offer solutions like:

- Precise current control to protect electrolyser stacks.

- Fast response to load changes, avoiding stress on equipment.

- Ripple control (<1%), extending stack life.

Wrapping Up

Today, where efficiency and reliability remain linchpins of success, advanced DC-DC converters wth MPPT and AI are proving to be strategic enablers of scalable, sustainable, and cost-effective hydrogen production.

By integrating intelligent control, reducing conversion losses, and ensuring redundancy, these modern converters enable electrolyser plants to achieve peak efficiency levels while adapting to the unpredictable nature of renewable power.

At YonderH2, we tailor power electronics that fuel the next generation of green hydrogen projects. If you are planning to build or upgrade an electrolyser plant, this is your sign to explore how an advanced DC-DC Converter with MPPT and AI can enhance your efficiency, lower LCOH, and future-proof your operations.

About the Author: Yonder, a division of the Ador Group, has been a leader in Power Electronics since 1908. Specializing in advanced Power Conversion Units for hydrogen generation, we integrate Alkaline, PEM, SOEC, and AEM electrolyzers to ensure high efficiency and minimal power consumption. Headquartered in Mumbai with state-of-the-art facilities in Pune, Yonder is committed to global decarbonization. Our 500-MW manufacturing facility for hydrogen power sources is poised to deliver cutting-edge solutions that thrive in unique and demanding deployment contexts.