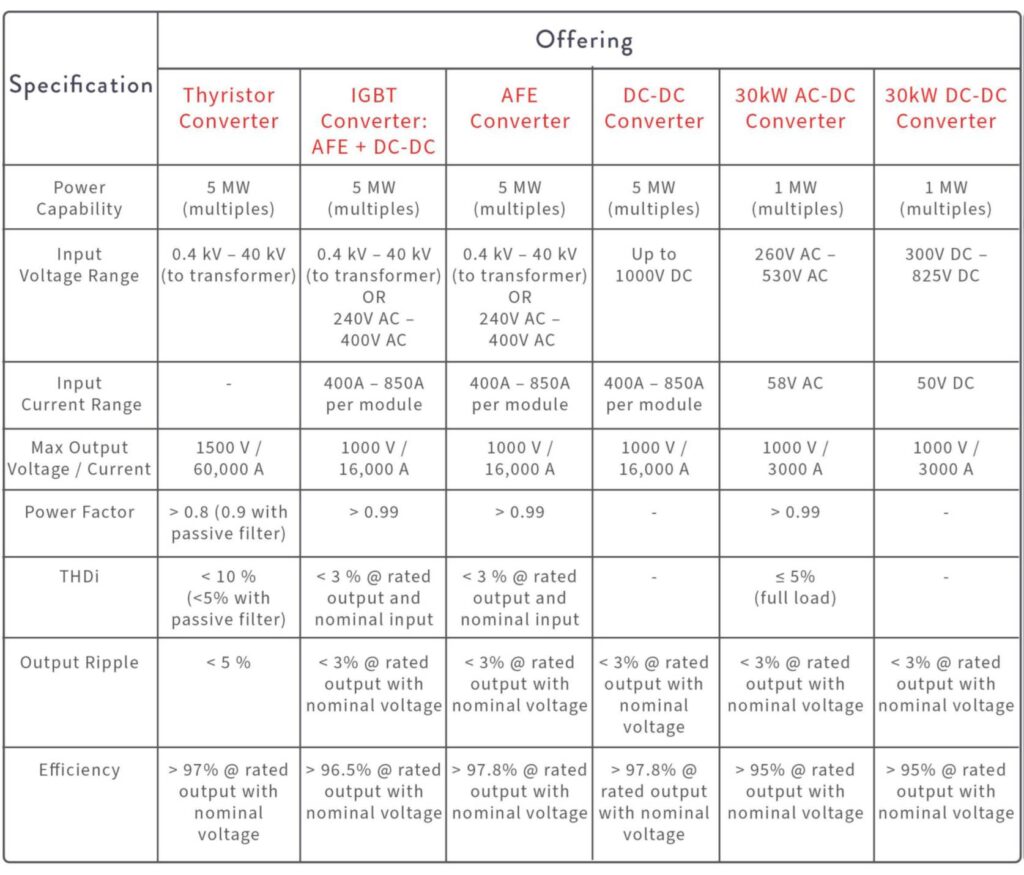

Insulated-Gate Bipolar Transistor (IGBT) technology provides High Efficiency, significant reduction in Harmonic Distortion (THDi) and can improve the Power Factor to near unity without the use of auxiliary components.

Yonder ofers IGBT-based converters across Active Front End, Active Front End with DC-DC Chopper and DC-DC technology. For kW-scale projects, we also offer SiC-based bidirectional convertors

Yonder Active Front-End (AFE) converter is designed to convert AC to DC using IGBT technology which employs higher frequency switching. AFE topology reduces harmonic distortion and allows bidirectional power exchange between AC and DC allowing regenerated power to be fed back to the supply (if needed). With already integrated filters, the module will provide smooth DC Voltage to the electrolyser with near unity Power Factor which will ensure minimum electricity consumption.

Ador offers a two-stage converter system employing a combination of Active Front End (AFE) and Phase Shift Modulation (PSM) technology. The AFE module converts the AC to constant DC voltage and with PSM technology, the constant DC voltage is converted to desired lower DC voltage.

In AFE stage the harmonics is significantly reduced while maintaining near unity power factor without additional harmonic filters and power correction circuitry. In DC-DC stage, the interleaved PSM technology provides a significant reduction in the output ripple.

Ador DC-DC Converter is designed to convert constant DC to variable DC using high frequency IGBT switching. Phase Shift Modulation (PSM) topology is used to operate the DC-DC converter, which offers reduction in the size of output filters.

This system is operated as connections of buck converters operated in parallel. This technology is ideal for direct solar to electrolyser connections. With already integrated filters, the module will provide DC Voltage with minimum ripple which will ensure the smooth operation of hydrogen electrolysers.

The silicon carbide (SiC) based semiconductor devices give better performance in terms of higher temperature operation and can be switched using higher frequency, which reduces the overall size of unit.

AC-DC converter is a two-stage converter system. In AC-DC module, first stage AFE is used, giving lower harmonics and almost unity power factor. In second stage based DC-DC converter is used to provide low ripple DC output as per customer requirement.

The DC-DC module uses a two-stage conversion system. In the first stage, variable DC is converted to higher fixed DC voltage. In the second stage, the fixed DC voltage is converted to low ripple DC as per specification. For solar to electrolyser DC-DC operations, built-in MPPT functions of the module will transfer maximum power throughout the day.

Yonderh2’s igbt rectifiers are engineered for high power and high-performance applications. Designed with high-frequency switching and advanced control circuits, these rectifiers offer precise voltage waveform control and efficient AC power to DC power conversion. Whether your operation involves green hydrogen production, renewable energy systems, or heavy-duty industrial equipment, Yonderh2 ensures reliable, energy-efficient performance.

An IGBT rectifier is a power conversion device that combines the high-speed switching of MOSFETs with the high voltage and high current handling capabilities of bipolar transistors. These rectifiers convert AC input into clean, stable DC output with exceptional efficiency. The result? Improved output voltage control, reduced power loss, and minimal rectified voltage distortion—key factors in mission-critical power supplies.

Compared to older silicon controlled rectifiers (SCRs) or thyristor-based systems, igbt rectifiers offer:

These benefits lead to lower operational costs and greater system reliability.

Yonderh2’s igbt rectifiers are specifically designed to support modern AC input and variable load environments. With high-frequency switching, they deliver smooth and controlled DC voltage, making them ideal for:

igbt rectifiers are critical for powering electrolyzers. Their stable DC output improves hydrogen yield, even under fluctuating AC voltage conditions from renewables.

They efficiently convert AC from solar panels and wind turbines to DC power suitable for storage or further conversion.

Yonderh2’s igbt rectifiers supply steady DC power to motors, drives, and electroplating systems, enabling higher productivity and lower maintenance.

Rapid, energy-efficient EV charging relies on igbt rectifiers’ ability to handle high voltage, manage voltage waveform quality, and optimize power factor.

Yonderh2’s rectifiers are equipped with intelligent control circuits to fine-tune output voltage and current, improving power supply responsiveness. Built-in IGBT control systems ensure accurate and stable DC voltage even under varying loads. These rectifiers are also compatible with SCRs to create hybrid systems tailored for specific applications.

The result: seamless integration with your existing infrastructure—no compromises on reliability or efficiency.

Whether you’re building a next-gen electrolyzer plant or upgrading your industrial power supplies, Yonderh2’s igbt rectifiers are built to last.

With growing global pressure to decarbonize, industries need power conversion systems that offer resilience, efficiency, and long-term sustainability. Yonderh2’s igbt rectifiers:

Yonderh2’s igbt rectifiers are used across a wide range of industries and applications where stable and efficient DC power is essential. In green hydrogen production, they provide consistent DC output to electrolyzers, enhancing hydrogen yield and reducing energy losses. In renewable energy systems, they efficiently convert AC input from solar panels and wind turbines into steady DC voltage, supporting grid stability and storage. For industrial drives and motors, these rectifiers ensure reliable DC power, reducing equipment wear and downtime. In electric vehicle charging stations, their high-frequency switching and power factor correction allow for fast, efficient charging. Additionally, they’re used in electroplating systems, where ripple-free DC power is critical for coating quality, and in both alkaline and PEM electrolyzers, where they ensure optimal performance through precise voltage control.

Future-proof your power infrastructure with rectification technology that delivers on performance, durability, and sustainability. Yonderh2’s igbt rectifiers offer a perfect combination of control system precision, high voltage performance, and advanced AC to DC power conversion.

Whether you’re navigating the shift to clean energy or enhancing your industrial efficiency, Yonderh2 provides rectifiers built for the future.

An Insulated-Gate Bipolar Transistor (IGBT) Converter is a power electronic device that efficiently converts AC to DC power. It offers high efficiency, significantly reduces harmonic distortion (THDi), and can improve the power factor to near unity without the need for auxiliary components.

Yonderh2 provides a range of IGBT-based converters, including:

AFE technology reduces harmonic distortion and maintains a near unity power factor without additional harmonic filters or power correction circuitry. This ensures smooth DC voltage supply to electrolysers, minimizing electricity consumption during hydrogen production.

Silicon Carbide (SiC) based converters operate at higher temperatures and can be switched at higher frequencies, resulting in a more compact unit size. They provide improved performance and efficiency in power conversion applications.

Yes, Yonderh2’s IGBT converters are designed for various applications, including renewable energy systems. For instance, the DC-DC rectifier with Phase Shift Modulation Technology is ideal for direct solar to electrolyser connections, ensuring efficient power conversion with minimal ripple.

Yonder DC Power Supplies are designed and manufactured for MW-scale hydrogen production.