How to Maintain Hydrogen Electrolysers for Long-Term Reliability

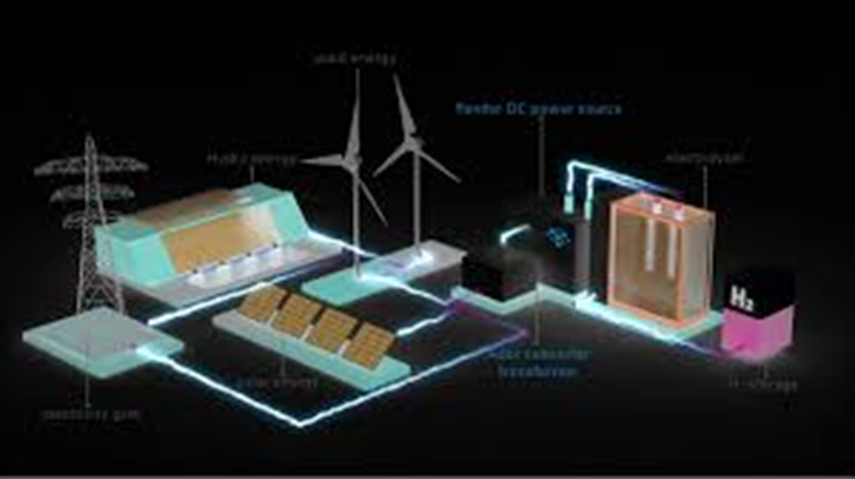

Ever wondered how long a hydrogen electrolyser can keep delivering its best? With the global shift towards sustainable energies, the rise of hydrogen is rising every day, making reliability and efficiency top priorities. Hydrogen electrolysers are the most crucial components in green hydrogen production systems, turning clean electricity and water into fuel for the future.

But like any other equipment, they need the right care as well. Skipping maintenance can result in shorter lifespans, reduced efficiency, and costly downtime. In this blog, we will understand the right approach that can help you keep them reliable for years.

The electrolyser stack is like the engine of your system; it’s where water molecules split into hydrogen and oxygen. Over time, it can wear down due to thermal stress, impurities in water, and current densities. Routine inspections are crucial. This helps identify early signs of corrosion, membrane thinning, or electrode degradation. Cleaning protocols using deionized water can prevent contamination.

Additionally, monitoring stack efficiency trends ensures that operators can replace the stack before its performance plummets. Maintenance is a cheaper option and safer than full-scale breakdowns.

Water electrolysers split water into hydrogen and oxygen to make hydrogen; thus, the quality of water matters a lot. Using pure treated water avoids scaling, corrosion, and several other issues that can damage the system. To achieve this, operators must keep filters fresh and check water purity regularly, which ensures your electrolyser runs smoothly and delivers cleaner hydrogen.

Electrolysers survive on the constant flow of electricity, and that’s what makes the power electronics like DC-DC converters, rectifiers, and transformers crucial. This necessitates regular inspections to monitor these components, including periodic calibration of DC-DC converters.

It maintains stable voltage and current levels, while routine checks on transformers and rectifiers prevent overheating. Adding an advanced MPPT helps optimize the use of renewable energy, ensuring the system remains both stable and reliable.

Purity is about efficiency and safety, both! Regularly calibrating hydrogen purity sensors ensures the gas meets quality standards. Additionally, leak checks are crucial to prevent hydrogen from escaping, which can be hazardous and wasteful. Thus, the operators must keep the safety valves, pressure relief system, and venting lines in good condition to add an extra level of protection.

Traditional maintenance methods are reactive, but what attracts operators is predictive maintenance, which utilizes AI and IoT tools. By connecting electrolysers to advanced monitoring platforms, operators can detect anomalies in temperature, voltage, and current profiles before they escalate, allowing for timely intervention. It helps schedule condition-based maintenance rather than fixed intervals and extends stack life by dynamically adjusting operation modes.

Maintaining electrolysers shouldn’t be stressful and complicated. A combined solution of regular checks, clean inputs, reliable power supply, and smart safety monitoring technologies can help your system run efficiently for years. At YonderH2, we help operators maintain this efficiency and reliability that go hand in hand.

So, suppose you are building a new electrolyser facility or optimizing an existing one. In that case, we offer solutions like DC-DC Converters for your hydrogen electrolysers, designed to keep your hydrogen production at its peak.