AC-DC Rectifiers in Green Hydrogen Production: Powering the Future One Waveform at a Time

Green hydrogen is making headlines, and rightfully so—it’s one of the most promising paths to a net-zero energy future. But behind every high-efficiency electrolyser lies a lesser-known hero: the AC-DC rectifier.

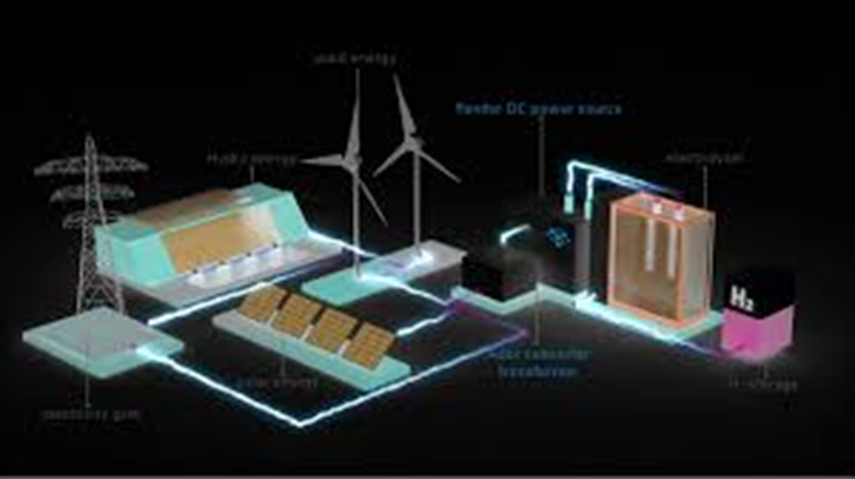

You see, while renewable energy sources like wind and solar often deliver power in alternating current (AC), electrolysis demands direct current (DC). And that’s where rectifier systems come in—quietly transforming AC to DC with precision, enabling the electrolysers to do what they do best: split water into hydrogen and oxygen.

In this blog, we break down how rectifiers work, the role of full wave rectifier circuits, and why getting your rectifier system right is crucial for efficiency, scalability, and long-term reliability in green hydrogen production.

Why Electrolysers Rely on DC Output Voltage

Electrolysis is a delicate electrochemical process. For water molecules to split cleanly, the electrolyser stack needs a steady, unidirectional DC output voltage. Any interruptions or fluctuations can reduce hydrogen production efficiency—or worse, damage components.

Unfortunately, the AC power provided by the grid alternates direction dozens of times per second, especially in a single-phase system. That’s where rectifiers come in. They take in AC and output a stable, filtered DC stream by eliminating the negative half cycles and smoothing the voltage with components like filter capacitors.

In short, if you want your electrolyser to run smoothly, you need a rectifier that can handle the job—especially at high voltage and high frequency.

How the Rectifier Converts AC to DC: The Core Concept

Let’s talk about the heart of the operation. A rectifier converts alternating current into direct current by manipulating the output waveforms. The most common design in hydrogen systems is the full wave rectifier circuit, which uses both halves of the AC input signal.

In a bridge rectifier, four diodes are arranged to route both the positive and negative half cycles of the AC waveform into a single-directional DC output. This is called achieving full wave rectification—and it’s far more efficient than half-wave systems.

After rectification, the ripple voltage—the small fluctuations remaining in the DC output—is further minimized using a filter capacitor, ensuring a smooth and constant supply of energy to the electrolyser.

So, from input to output, a rectifier’s mission is clear: take volatile AC, and turn it into clean, regulated, ready-to-use DC power.

Exploring Types of Rectifiers for Hydrogen Production

In green hydrogen facilities, you’ll typically find these types of rectifiers doing the heavy lifting:

- Bridge Rectifiers: Popular for their efficiency and compactness, these are great for applications where simplicity meets performance. They don’t require a center tap and are ideal for handling high voltage and high frequency scenarios.

- Centre-Tapped Transformer Rectifiers: These use two diodes and a transformer with a central tap on the transformer secondary winding. They’re highly effective in some DC power supplies, though more complex in design.

Both types support full wave rectifiers that ensure higher energy efficiency and smoother DC output voltage, which is crucial when powering large-scale hydrogen electrolysers.

Why High-Frequency and Low-Ripple Rectification Matters

As hydrogen production scales, the demand for high frequency, robust rectifier systems becomes more urgent. Not only must these systems convert power cleanly—they must also adapt to fluctuating renewable energy inputs from sources like solar or wind.

In advanced setups, switch-mode rectifiers are used to handle these dynamic conditions, keeping output voltage of the rectifier stable, minimizing ripple, and protecting the system against electrical stress.

With such systems, hydrogen producers benefit from reduced energy losses, extended component lifespan, and predictable hydrogen output—even when the grid isn’t playing nice.

What Rectifier Systems Mean for Green Hydrogen Operations

Choosing the right rectifier system affects more than just electrical conversion—it touches every aspect of the hydrogen production process:

- It improves energy efficiency, reducing electricity costs.

- It ensures output consistency, which leads to predictable hydrogen purity and volume.

- It extends the life of the electrolyser stack by minimizing electrical stress.

- It enables scalability, allowing for modular or large-scale hydrogen facility setups.

- It supports integration with renewable grids that deliver single-phase, variable frequency AC power.

In other words, your rectifier system is not just a power adapter—it’s the backbone of your hydrogen plant’s performance.

Final Thought: Powering Green Hydrogen with Precision

From bridge rectifiers to high-frequency full wave rectifiers, these technologies aren’t just support players—they’re enablers of the green hydrogen revolution. As demand for clean fuel grows, the pressure is on to design smarter, more resilient infrastructure. That starts with understanding—and selecting—the right rectifier system.

Because when your electrolyser runs on pure, stable DC power, everything else falls into place: energy efficiency, hydrogen purity, and system reliability.

Power Green Hydrogen Right—Partner with YonderH2

At YonderH2, we bring deep expertise in AC-DC rectification, high-performance DC power supplies, and custom-engineered solutions tailored for green hydrogen production. From choosing the ideal full wave rectifier circuit to designing low-ripple, high-frequency conversion systems, we make sure every watt works in your favour.

Ready to turn your power input into hydrogen output?

Talk to YonderH2—where innovation meets execution, and every rectifier counts.