Understanding the Role of AC-DC Rectifiers in Green Hydrogen Production

What is an AC-DC Rectifier?

An AC-DC rectifier is an electrical device that converts alternating current (AC) from the power grid into direct current (DC)—a crucial requirement for operating devices that rely on stable, one-directional voltage. In green hydrogen production, rectifiers are essential for powering electrolysers, which need consistent DC power to split water into hydrogen and oxygen through electrolysis.

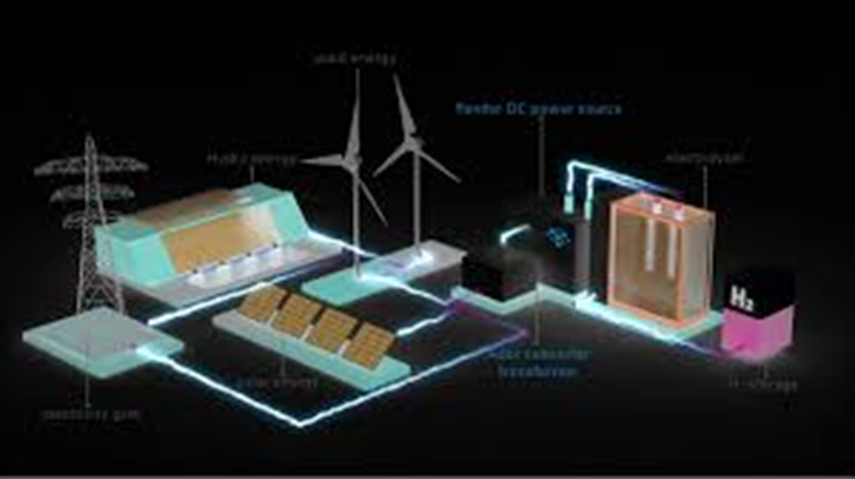

As green hydrogen gains momentum as a clean energy solution, the focus is shifting to the technologies that power its production. At the heart of every efficient electrolyser lies one critical component: the AC-DC rectifier. This powerful device enables the transformation of AC voltage from the grid into stable DC voltage required for electrolysis—the process that splits water into hydrogen and oxygen.

But how does this conversion happen? And why is it so important for the future of hydrogen production?

In this blog, we will break down the fundamentals of rectifier circuits, explore key types like the bridge rectifier and center-tapped transformer systems, and explain why rectifier systems are essential to reliable and scalable green hydrogen facilities.

1. Why Electrolysers Need DC Power

Electrolysers require a stable and continuous flow of DC voltage to operate efficiently. The electrochemical reaction that generates hydrogen depends on a constant polarity and consistent power supply, something that alternating current (AC input) simply can’t provide.

That’s where AC-DC rectifiers step in. These systems convert alternating current (AC) from the power grid into smooth, usable DC for the electrolyser stack, enabling precise control and optimal energy use.

2. The Basic Principle: AC to DC Conversion

An AC-DC rectifier works by flipping or smoothing the AC signal into a unidirectional flow. The most common technique involves a rectifier using four diodes arranged in a configuration known as a bridge rectifier.

Here’s how it works:

- During the positive half-cycle of the AC voltage, two diodes conduct and allow current to flow.

- During the negative half-cycle, the other two diodes conduct, directing current in the same direction.

- This results in achieving full wave rectification, both halves of the AC input contribute to the output, enhancing efficiency.

This process is the core of how a rectifier converts AC to DC.

3. Types of Full Wave Rectifiers

There are two primary types of full-wave rectifiers used in green hydrogen systems:

a. Bridge Rectifier

- Uses four diodes

- No need for a central tap

- Compact and efficient

- Common in high voltage applications where space and simplicity matter

b. Centre Tapped Transformer Rectifier

- Requires a special centre-tapped transformer

- Uses only two diodes

- Slightly more complex but efficient in certain configurations

Both types can be used in high-frequency environments, especially in advanced switched-mode power supply (SMPS) setups, where energy efficiency and precision are top priorities.

4. High-Frequency and Industrial-Grade Rectifier Systems

Modern green hydrogen plants often use advanced rectifier systems capable of handling high frequencies and demanding loads. These systems are typically integrated with digital controllers and cooling technologies to ensure optimal performance.

Additionally, dc power supplies in industrial settings are engineered to withstand fluctuations, protect against surges, and ensure consistent energy flow to the electrolyser, making the rectifier circuit one of the most mission-critical components in the system.

5. Why Rectifier Choice Matters in Green Hydrogen Production

The right rectifier technology can impact:

- Energy efficiency

- Hydrogen output consistency

- Component lifespan

- Operational cost

Choosing between a simple bridge rectifier and a switched-mode power supply setup can affect how well your system responds to high voltage demands and fluctuating AC input.

For large-scale or modular hydrogen systems, investing in robust, scalable rectifier systems isn’t optional, it’s essential.

In Summary

From converting raw AC voltage into clean, regulated DC voltage, to powering the electrolysers that generate hydrogen, AC-DC rectifiers are indispensable in the green hydrogen value chain. Understanding their design, application, and impact ensures you’re building an energy system that’s both reliable and future-ready.

Turn Current Into Capability—With YonderH2

At YonderH2, we don’t just power electrolysers, we power possibilities. Our expertise in AC-DC rectifier systems, DC power supplies, and hydrogen-ready infrastructure ensures your green hydrogen plant runs with precision, efficiency, and performance you can trust.

As the green hydrogen economy accelerates, the demand for high-efficiency, reliable power conversion technologies becomes paramount. One of the foundational components of any electrolysis system is the AC-DC rectifier. These devices convert alternating current (AC), typically sourced from the electrical grid or renewable sources, into direct current (DC), which is essential for driving electrolyzers—the core technology in hydrogen production.

The Critical Function of AC-DC Rectifiers

Electrolysers require a stable, controlled DC input to split water into hydrogen and oxygen effectively. While renewable energy sources such as wind and solar generate electricity in variable patterns, rectifiers act as the critical link in ensuring that this fluctuating AC power is converted into the stable DC power needed for efficient hydrogen production.

The design and performance of AC-DC rectifiers directly affect the energy efficiency, system reliability, and operational cost of a green hydrogen plant.

Key Benefits of AC-DC Rectifiers in Hydrogen Production

1. Energy Efficiency Gains: High-efficiency AC-DC rectifiers minimize power losses during conversion, ensuring that more input energy is utilized for actual hydrogen generation. Advanced rectifiers can achieve efficiencies exceeding 98%.

2. Scalability and Modularity: Modern rectifier solutions are modular and scalable, which supports small-scale distributed hydrogen systems as well as large industrial installations.

3. Grid Compatibility: AC-DC rectifiers can be designed to interface seamlessly with renewable energy sources and meet strict grid codes. This is vital for ensuring power quality and grid stability, particularly when integrating variable renewables.

4. Power Quality Management: Through active filtering and power factor correction, AC-DC rectifiers help reduce harmonic distortion, voltage fluctuations, and reactive power draw.

Applications Across Electrolyser Technologies

Different electrolyser technologies—PEM (Proton Exchange Membrane), alkaline, and solid oxide—have varying requirements for voltage, current, and control. Advanced AC-DC rectifiers can be customized to meet the specific power profiles of each, providing tailored solutions for different production environments.

For instance: · PEM electrolysers benefit from high-frequency, fast-switching rectifiers that enable rapid ramp-up and down. · Alkaline electrolyzers typically require robust, stable DC output over longer cycles.

Integration with Digital Control and Monitoring

Today’s AC-DC rectifiers are increasingly equipped with digital interfaces and smart control features. These enable predictive maintenance, real-time diagnostics, remote control, and integration into plant-wide energy management systems. This connectivity enhances system uptime, operational safety, and long-term performance.

Conclusion

AC-DC rectifiers are far more than simple conversion devices; they are strategic enablers in the green hydrogen value chain. By ensuring efficient, stable, and intelligent power delivery to electrolysers, they help optimize the overall performance and economics of hydrogen production systems.

As the industry scales, selecting the right AC-DC rectifier technology will be a critical design decision for project developers and integrators committed to delivering cost-effective and sustainable hydrogen.

#ACDCRectifiers #GreenHydrogen #ElectrolyserPower #HydrogenInfrastructure #CleanEnergy #PowerElectronics #HydrogenEconomy