Understanding AC-DC Rectifiers: How They Work and Why They're Essential

An AC to DC rectifier is an essential electronic device used to convert Alternating Current (AC)—which periodically reverses direction—into Direct Current (DC), where the electric charge flows consistently in one direction. This conversion is crucial because most electronic circuits and devices (like smartphones, computers, and LED lighting) require stable DC power to operate efficiently.

AC-DC Rectifiers: Key to Reliable Power Conversion

Yonder is leading innovation in power conversion with advanced Thyristor Rectifiers and DC-DC converters designed for efficiency, precision, and durability. Our Thyristorised AC-DC rectifiers, available from 6-pulse to 48-pulse configurations, offer exceptional load regulation and long-term performance for industrial and commercial applications.

The rectification process involves several stages:

- Rectification using diodes or semiconductor switches, which allow current to pass in only one direction, blocking the reverse flow.

- Filtering, typically with capacitors or inductors, to smooth out the pulsating DC and reduce voltage ripple.

- Voltage regulation to maintain a consistent output voltage, even when the input AC voltage or load changes.

Rectifiers can be found in power supplies, battery chargers, and virtually any device that plugs into an AC outlet but runs on DC power internally.

Emerging Trends in Rectifier Technology

- Advanced Semiconductor Materials

The adoption of wide bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN) is revolutionizing rectifier performance. These materials offer superior thermal conductivity and higher breakdown voltages, enabling faster switching speeds and reduced energy losses. Such advancements are particularly beneficial in high-performance applications, including electric vehicles and renewable energy systems .

- Modular and High-Frequency Designs

Modular rectifier systems provide scalability and flexibility, allowing customization to specific application requirements. High-frequency rectifiers, operating beyond traditional 50–60 Hz ranges, facilitate compact designs and improved efficiency, aligning with the growing demand for space-saving solutions in various industries .

- Integration of Smart Technologies

The incorporation of digital control technologies, such as microcontrollers and digital signal processors (DSPs), enables precise control over rectification processes. This integration allows for adaptive modulation techniques, enhancing efficiency under varying load conditions. Additionally, the rise of Internet of Things (IoT) connectivity facilitates remote monitoring and diagnostics, optimizing performance and reducing downtime .

- Hybrid Rectifier Topologies

Innovative hybrid rectifier designs, such as those combining silicon-controlled rectifiers (SCR) with modular multilevel converters (MMC), are emerging to meet the demands of high-power applications like electrolytic hydrogen production. These configurations effectively mitigate AC-side harmonics and minimize DC-side ripple, enhancing conversion efficiency and grid compatibility.

- Sustainability and Energy Efficiency

As industries prioritize eco-friendly solutions, rectifier technologies are evolving to minimize energy loss and enhance efficiency. The integration of advanced materials and designs not only improves performance but also aligns with global sustainability goals, particularly in sectors like renewable energy and electric vehicles.

AC-DC Rectifiers: Key to Reliable Power Conversion

Yonder is leading innovation in power conversion with advanced Thyristor Rectifiers and DC-DC converters designed for efficiency, precision, and durability. Our Thyristorised AC-DC rectifiers, available from 6-pulse to 48-pulse configurations, offer exceptional load regulation and long-term performance for industrial and commercial applications.

In collaboration with Ador, our next-gen DC-DC rectifier uses high-frequency IGBT switching and Phase Shift Modulation (PSM) to convert constant DC to variable DC with minimal ripple—ideal for hydrogen electrolyser systems and direct solar-to-electrolyser setups.

Bridge Rectifier and Full-Wave Rectification

A bridge rectifier is a common rectifier circuit configuration that uses four diodes to convert alternating current (AC) into direct current (DC), effectively achieving full wave rectification without needing a center tapped transformer. In this setup, the AC input is applied across the bridge, and during each half-cycle, two diodes conduct to allow current flow in one direction, converting the AC signal to a pulsating DC voltage. This approach ensures both the positive and negative halves of the waveform contribute to power delivery, making it highly efficient for DC power supplies.

Rectifier systems are crucial in various applications, especially where high voltage or high frequencies are involved, such as in switched mode power supply (SMPS) systems. A rectifier converts an AC voltage into DC voltage for stable power delivery in electronics, industrial control, and telecommunication infrastructure. Whether it’s AC to DC conversion in small chargers or in complex industrial equipment, full wave rectifiers remain fundamental in converting AC to DC effectively and reliably.

Why AC-DC Rectifiers Matter:

- Function: Convert fluctuating AC to steady DC for electronics and industrial systems.

- Applications: From smartphones and laptops to electrolysers and heavy machinery.

- Benefits: Improves energy efficiency, protects devices, ensures consistent performance.

What to Look for in a Rectifier:

- Voltage & current capacity

- Load stability

- Quality components (e.g., IGBTs, thyristors)

- Trusted manufacturers

Modern controlled rectifiers and smart converters enhance performance, reduce power loss, and support advanced applications like renewable energy integration. Whether for home electronics or critical infrastructure, choosing the right rectifier ensures safety, longevity, and operational efficiency.

Types of Rectifiers

Rectifiers come in different types, each suited for specific applications:

Half-Wave Rectifier

Uses a single diode to convert AC to DC.

It is simple but inefficient, as it only utilizes one-half of the AC cycle, resulting in a pulsating DC output.

Commonly used in low-power applications where efficiency is not critical.

Because only one half of the input waveform is used, the average output voltage is relatively low, and the output contains significant ripples, making it unsuitable for sensitive electronics without additional filtering.

Full-Wave Rectifier

Utilizes two diodes and a center-tapped transformer, or four diodes in a bridge configuration, to convert both halves of the AC cycle into DC.

It is more efficient, providing a smoother DC output with fewer ripples.

In center-tap designs, each half of the AC waveform is routed through a different diode, effectively doubling the frequency of the output voltage.

These rectifiers are widely used in power supply units and battery chargers where a stable DC voltage is needed.

Bridge Rectifier

A popular type of full-wave rectifier that uses four diodes arranged in a bridge configuration.

Offers full-wave rectification without needing a center-tapped transformer, making it versatile and widely used.

It is ideal for converting mains AC to DC in home appliances and industrial power systems.

The bridge rectifier’s design ensures a more compact and cost-effective solution compared to the center-tapped alternative.

How Rectifiers Convert AC to DC

Rectifiers use diodes and semiconductor devices that allow current to flow in only one direction. In a half-wave rectifier, the diode conducts during the positive half of the AC cycle, blocking the opposing half, resulting in a pulsating DC output. Full-wave rectifiers, however, utilize both halves of the AC cycle by inverting the opposing half and combining it with the positive half. This produces a smoother DC output, reducing the need for additional filtering. Bridge rectifiers enhance this process by configuring four diodes to ensure full-wave rectification, providing a consistent and efficient DC output.

This process is essential for powering devices that require a constant voltage. However, even after rectification, the resulting DC signal may still have fluctuations known as ripples. To address this, filter circuits—typically involving capacitors and inductors—are added to smooth out the voltage and provide clean DC power suitable for sensitive electronic components.

Role of Rectifiers in Green Hydrogen Production

AC-DC rectifiers are a cornerstone of the green hydrogen production process, converting alternating current (AC) from renewable energy sources into the direct current (DC) needed for water electrolysis. This conversion is critical for ensuring the electrolyser receives a consistent and stable power supply, allowing for efficient splitting of water into hydrogen and oxygen. Modern rectifiers are engineered to optimize this process by minimizing energy losses and improving power quality, ultimately supporting the scalability of green hydrogen systems.

In addition to their efficiency, advanced rectifiers enhance the durability of electrolysis systems by reducing heat generation and incorporating robust cooling mechanisms. They also address power quality issues such as harmonic distortion, which can negatively impact the performance of sensitive electrolysis equipment. By stabilizing energy flow and protecting the system from fluctuations, rectifiers enable reliable operations, even when integrated with intermittent renewable energy sources like solar and wind.

Rectifier technology is continuously evolving to meet the demands of industrial-scale hydrogen production. Innovations like pulse-width modulation (PWM) and power factor correction not only improve energy utilization but also lower operational costs. As the green hydrogen economy expands, these advancements ensure that rectifiers remain a key component in achieving cost-effective and sustainable hydrogen production at megawatt scales.

Applications of Rectifiers

Rectifiers are used in a wide variety of applications:

Consumer Electronics: Power supplies for televisions, radios, gaming consoles, and desktop computers depend on rectifiers to convert the incoming AC from wall outlets into the required DC voltage levels.

Battery Charging Systems: Rectifiers play a central role in converting AC to DC for charging applications, including smartphones, laptops, electric vehicles (EVs), and industrial battery banks used in backup power systems.

Industrial Equipment: Many heavy-duty systems like welding machines, variable speed drives for motors, and electroplating equipment rely on high-power rectifiers to deliver controlled and steady DC power.

Telecommunication Systems: Rectifiers are crucial in telecom power supplies, where uninterrupted DC is required for network switches, base stations, and data centers.

Medical Devices: Many diagnostic and monitoring machines require low-ripple DC power, which makes the role of precision rectifiers vital in healthcare technology.

Advantages and Limitations

Advantages:

Efficient and reliable conversion of AC to DC.

Simple design, leading to high durability and low maintenance.

Relatively inexpensive and easy to implement.

Full-wave and bridge configurations offer high output with better voltage regulation.

Modern rectifiers are compact and energy-efficient, suited for both small and large-scale applications.

Limitations:

Half-wave rectifiers are less efficient, utilizing only one-half of the AC cycle.

Pulsating DC output may require additional filtering for smooth operation in sensitive devices.

Full-wave and bridge rectifiers, while more efficient, are more complex and costly.

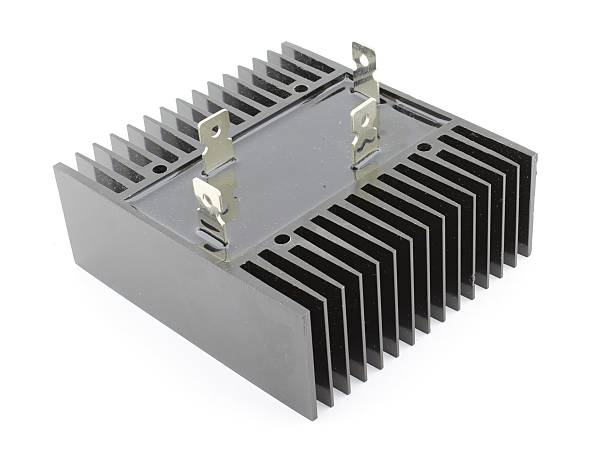

High-power rectifiers may require bulky heat dissipation systems to manage thermal loads.

Without proper filtering, rectified outputs can lead to electromagnetic interference (EMI) in nearby circuits.

Why is AC to DC Conversion Necessary?

AC power is generally used for transmission because it’s more efficient over long distances. However, DC power is more suitable for electronic devices, batteries, electric vehicles, and industrial automation systems. Therefore, converting AC to DC ensures the safe, efficient, and stable functioning of modern electrical systems.

Some common reasons for using AC DC rectifiers include:

- Providing power to digital circuits

- Charging batteries

- Supplying constant voltage to sensitive electronics

- Powering DC motors and drives

- Ensuring uninterrupted power supply (UPS)

Why AC-DC Rectifiers Are the Heart of Modern Power Systems

It’s easy to think of an AC-DC rectifier as just a small step in the power conversion process—but in reality, it’s the gatekeeper that decides how efficiently and reliably your devices run. From the charger in your phone to the multi-megawatt rectifiers in industrial hydrogen plants, these systems ensure that fluctuating AC from the grid is transformed into smooth, stable DC power. A high-quality AC to DC rectifier not only protects sensitive electronics from voltage spikes but also improves overall energy efficiency, reducing operating costs over time. Whether it’s a compact bridge rectifier for home electronics or a large-scale industrial AC-DC rectifier for manufacturing lines, the role is the same: deliver clean, dependable power exactly when and where it’s needed.

Choosing the Right AC-DC Rectifier for Your Application

Not all rectifiers are created equal, and selecting the wrong one can impact efficiency, safety, and lifespan of your equipment. Modern high-efficiency AC DC conversion technology uses advanced semiconductors, intelligent control systems, and low-loss designs to meet the demands of everything from medical devices to renewable energy integration. For instance, a precision-controlled AC-DC rectifier in a data center must maintain power quality under fluctuating loads, while a rectifier for electrolysis must handle high currents continuously with minimal ripple. Working with an experienced engineering partner ensures you get the right design, configuration, and capacity for your needs—turning your rectifier from just a component into a long-term investment in reliability and performance.

Why Choose YonderH2 Rectifier Solutions?

At YonderH2, we design and deliver advanced AC DC rectifier solutions tailored for mission-critical applications. Whether you’re operating in industrial, automotive, or renewable sectors, our rectifiers offer:

- High energy efficiency

- Compact, modular design

- Superior thermal management

- Seamless integration with renewable sources

- Industry-compliant safety features

Our team works closely with clients to offer customized, scalable solutions that meet unique power requirements.

Contact us today at info@yonderh2.comto discuss your project needs.

#ACDC #Rectifiers #PowerConversion #Electronics #ElectricalEngineering #AdorPower #EfficientPower #TechSolutions #EnergyEfficiency #PowerSupply