Hydrogen stands at the vanguard of the global shift to sustainable energy. Governments are working towards decarbonization, which has made hydrogen electrolysers essential for the production of green hydrogen on a large scale. To create an efficient system, it is crucial to pick the correct equipment for better performance, reliability, and cost-effectiveness.Let us dive into the key factors to help devise and execute a clean hydrogen generation system.

1. Evaluate the type of electrolyser technology

First, you need to choose the right hydrogen electrolyser type that aligns with project efficiency, cost, and scale. Alkaline electrolysers are trusted for their durability and affordability and are perfect for large-scale installations.

At the same time, PEM electrolysers deliver faster response times and are ideal for renewable-powered systems. SOE technology is an emerging technology that offers higher efficiency at high temperatures. Selecting the right technology is responsible for long-term efficiency and maintenance costs.

2. Consider power supply and conversion systems

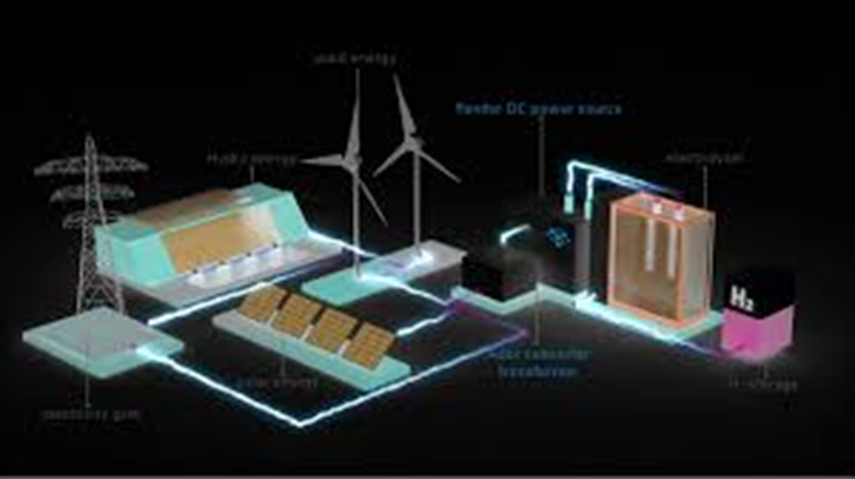

Since renewable energy sources like solar and wind can fluctuate, a stable and efficient power supply is vital. A reliable power conversion setup includes:

- Rectifiers

- Converters

- Transformers

This ensures consistent voltage and current delivery.

3. Focus on water quality and feedstock management

Water purity = Hydrogen purity.

Contaminated water can reduce efficiency and damage components. Therefore, incorporating high-quality water treatment systems is critical to enhance long-term reliability. This helps in reducing operational expenses and environmental effects, making your hydrogen production more efficient.

4. Design for cooling, safety, and maintenance

The hydrogen generation process generates a large amount of heat that requires a robust cooling system. It helps to maintain stable operating conditions. The safety systems are also crucial to monitor gas leaks, pressure levels, and temperature changes. Whereas maintenance technologies help to detect faults, resulting in lower downtime and optimizing overall performance.

5. Integrate Smart Control and Monitoring Systems

Modern hydrogen facilities rely on automation and digitalization for efficiency and scalable technology. Smart control systems use live or real-time instrumentation data to enable optimized performance by relating to power input energy balances, grid integration, and ultimately, lowering costs and improving efficiency. Advanced monitoring software will allow operators to track hydrogen output and inefficiencies through the capabilities of instant adjustments. These systems offer stability, better performance, and efficiency.

Conclusion

Selecting the proper electrolysis equipment is the key to a thriving clean hydrogen undertaking. Every decision is responsible for shaping the sustainability of the system, from choosing the right hydrogen electrolyser technology to ensuring precise control and safety mechanisms.

At YonderH2, we design, craft, and implement top-notch solutions for hydrogen generation.

Our team has decades of expertise in electrolysis systems, power conversion, and smart integration.

Suppose you are planning to build your clean hydrogen facility with confidence. Contact YonderH2 today to learn about the right electrolysis and integration solutions for your project.