There is a shift to clean energy globally, and hydrogen is becoming the foundation of the green solution. Building hydrogen through water electrolysis is a proven carbon-free process, but optimising this for industrial scale needs planning, technology and operational accuracy. Optimisation means maximum hydrogen yield, lower energy costs and industrial output.

Let us look into how industries can optimize the electrolysis process to attain efficiency and sustainability.

1. Choose the right electrolyser technology

Choosing the right electrolyser is the first step to efficient hydrogen production. Hydrogen production electrolysis can be done with different technologies, each for different goals. Proton Exchange Membrane (PEM) electrolysers respond quickly to fluctuating renewable energy inputs, perfect for solar or wind-powered plants.

Alkaline electrolysers are more durable and cost-effective for steady, large-scale production. SOEC (Solid Oxide Electrolysis Cells) is known for delivering high efficiency and helps in balancing scalability and long-term operational costs.

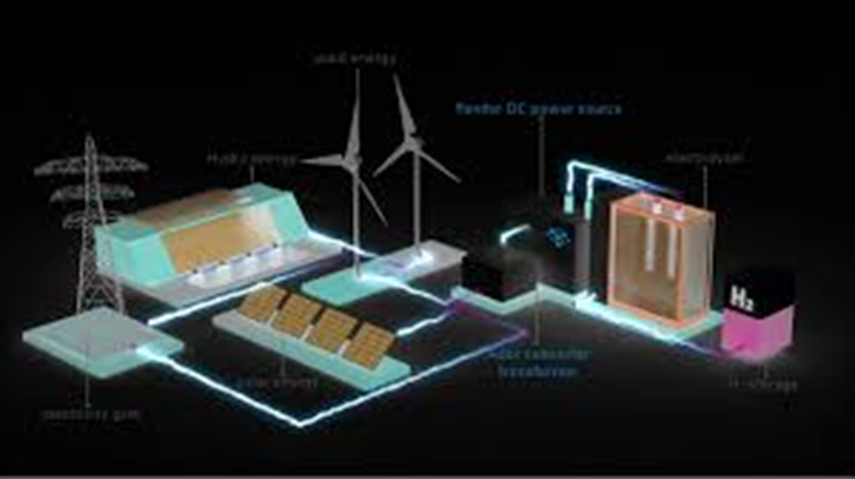

2. Optimise power supply and integration

Electrolysers need a stable DC power supply to produce hydrogen consistently. Industrial facilities powered by renewable energy, like solar and wind, can have variability that affects performance. Power conversion systems ensure constant energy flow, allowing the plant to operate smoothly even under fluctuating conditions. Power integration is necessary to increase hydrogen production, reduce losses, and smooth operations.

3. Secure a high-quality water supply

Water purity is the key to efficient electrolysis. Impurities can be a cause behind lower hydrogen yield. A powerful water treatment system and filtration support maintain uniform quality. Effective feedstock management enhances both efficiency and sustainability and lowers operational costs, such as recycling and treating by-products.

4. Implement thermal management and monitoring

The hydrogen production process generates excess heat and must be controlled for stable operations. Integrating effective cooling systems can prevent overheating and increase equipment life. Automated monitoring can help in detecting anomalies, adjusting parameters, and delivering efficient results. Predictive maintenance helps prevent downtime that results in a continuous flow of hydrogen production essential for industrial applications.

5. Scalability and flexibility

Industrial hydrogen demand can change with production cycles or market requirements. Design modular, scalable electrolyser systems for phased growth without major rework. Integration with smart grid and automation means the plant can adjust to unstable energy inputs and operational requirements. An adaptable design future-proofs the structure, keeps it cost-effective and ready for new technologies.

Conclusion

Optimising hydrogen production electrolysis for industry requires planning, advanced equipment and smart integration. From selecting the correct electrolyser to water supply, power systems, thermal management and scalable design, every stage impacts hydrogen output. Industries implementing these best methods will be prepared for increasing energy demand, sustainability, and operational excellence.

At YonderH2, we specialise in integrated solutions for industrial hydrogen production. Our expertise in electrolysis technology, power conversion systems, and smart plant integration means your facility will be safe, efficient and performing at its best.

Ready to optimise your industrial hydrogen production?

Contact YonderH2 today to talk to us about customised solutions to boost water splitting efficiency and hydrogen output for your business.