The global transition to clean energy is no longer a pursuit; it is an involved mission. At the heart of this shift lies hydrogen, one of the most encouraging clean energy bases. A green hydrogen plant is where this commitment takes form. It is where water and renewable power come together to produce hydrogen, a clean and adaptable fuel that can power everything from factories to vehicles. Fantastic right? Thoughtful way to build clean energy.

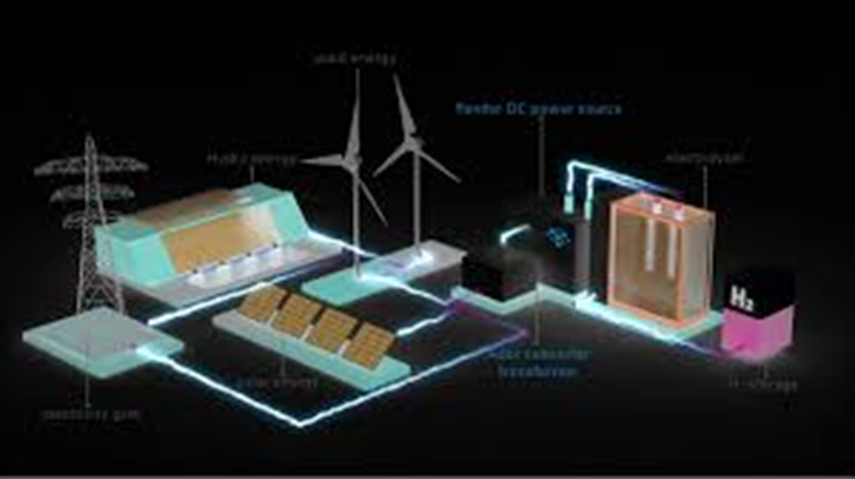

Green hydrogen plants are paving the way for a sustainable future. By integrating solar and wind power with electrolysis, industries can produce hydrogen on a large scale efficiently. However, to ensure everything works smoothly, intelligent energy management and long-term planning are crucial.

Let us dive in!

Steps in Designing and Implementing a Large-Scale Hydrogen Facility

1. Assess Site Feasibility and Renewable Power Possibility

Start with a site study. Assess local solar irradiance, wind potential, and grid connection. Locating the plant near renewable sources can help cut transmission losses and costs. A hybrid configuration that utilizes both wind and solar energy ensures continuous availability around the clock.

2. Choose the Most Suitable Electrolyser Technology

Your electrolyser is where efficiency and cost meet.

- PEM (Proton Exchange Membrane)

- Alkaline electrolysers

- SOEC (Solid Oxide Electrolysis Cells)

Choose the one that fits your capacity, hydrogen purity and environment.

3. Power Conversion and Control Systems

A green hydrogen plant uses power electronics like rectifiers, DC-DC converters and transformers. This avoids energy losses and offers excellent voltage regulation. Intelligent control systems align renewable power with electrolyser demands, helping the plant run smoothly even in fluctuating energy conditions.

4. Develop a Comprehensive Storage Plan and Transport Strategy

The most critical part of the hydrogen development process is the transportation. Once produced, the hydrogen must be safely stored. Choose between compressed gas, liquefied hydrogen, or ammonia conversion, depending on the mobility and industrial fuel requirements. Implement robust safety systems to international standards.

5. Plan for Scalability and Grid Stability

Modular stability is the key to designing and implementing a large-scale plant successfully. It offers incremental growth that aligns with growing technology and needs. Further, mechanisms such as grid balancing and energy management software can help stabilize processes when renewable energy fluctuates.

Final Thoughts

Be a part of the global clean energy revolution. However, you are apprehensive about proceeding, as designing and implementing a large-scale green hydrogen plant seems overwhelming. Every phase is critical, right from site inspection to system alignment. All these steps are vital and are responsible for shaping the efficiency and sustainability of the plant.

If you’re considering renewable-powered hydrogen production or scaling up your project, contact YonderH2 today. Bring your clean energy vision to life.

About the Author:

Yonder, a division of the Ador Group, has been a leader in Power Electronics since 1908. We specialise in advanced Power Conversion Units for hydrogen generation, we integrate Alkaline, PEM, SOEC, and AEM electrolyzers to ensure high efficiency and low power consumption. Headquartered in Mumbai with state of the art facilities in Pune,

Yonder is committed to global decarbonization. Our 500-MW manufacturing facility for hydrogen power sources is designed to deliver solutions that thrive in unique and demanding deployment scenarios.